What should be noted in the PCB board welding

o-leading.com

o-leading.com

2017-06-06 10:53:04

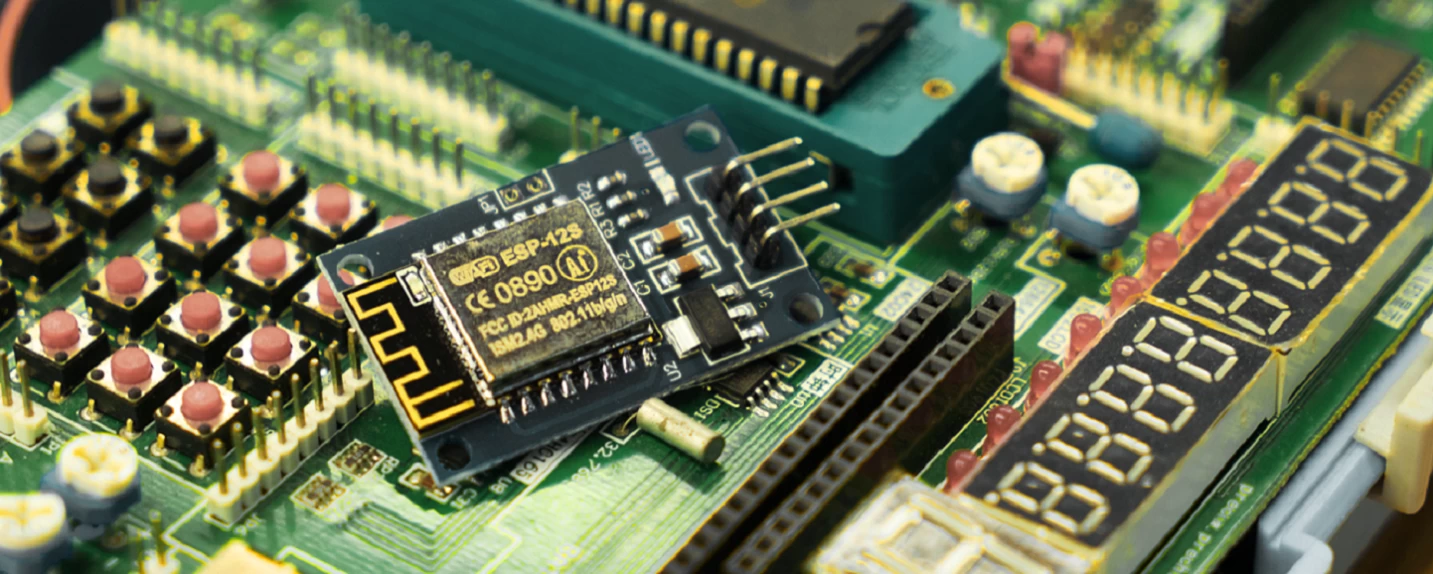

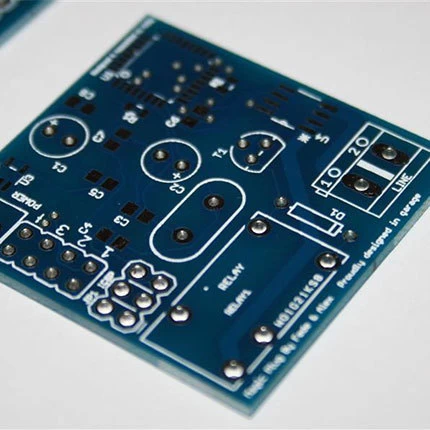

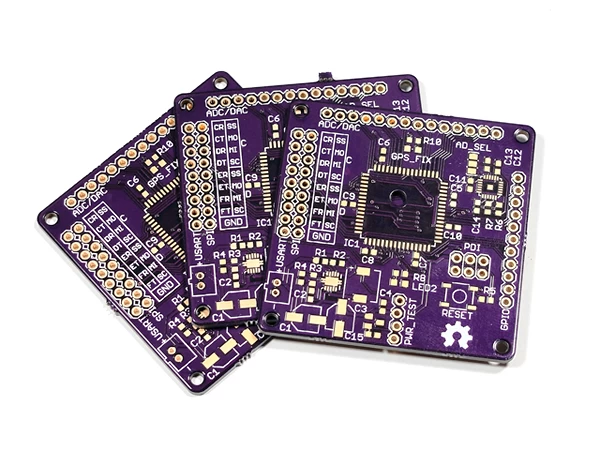

Welding is Printed circuit board supplier of electronic products in the assembly process is one of the important links.If there is no corresponding welding process quality assurance, any a well-designed electronic device are difficult to achieve the design index, Thick copper pcb wholesales china through years of welding industry, summed up a set of perfect welding process. Therefore, the following must be done in welding:

1. The welding surface must be kept clean. Even welders with good weldability, due to long-term storage and contamination, the surface of the weldment may produce harmful oxide film, oil and so on. Therefore, in the implementation of welding must be cleaned before the surface, otherwise it is difficult to guarantee the quality.

2. When welding temperature, time should be appropriate, heating evenly. When welding, the solder and the welding metal are heated to the welding temperature so that the molten solder is wetted and diffused on the surface of the metal to be welded and forms a metal compound. Therefore, to ensure that the solder joints are firm, be sure to have the appropriate welding temperature. At a sufficiently high temperature, the solder can be sufficiently wetted and sufficiently diffused to form an alloy layer. Excessive temperature is not conducive to welding. The welding time has a great influence on the solderability of the solder, the welding element, and the formation of the bonding layer. Correctly grasping the welding time is the key to high quality welding.

3. The solder joints should have sufficient mechanical strength. In order to ensure that the weldment is subject to vibration or shock will not fall off, loose, therefore, require the solder joints to have sufficient mechanical strength. In order to have sufficient mechanical strength of the solder joint, it is generally possible to use the method of bending the lead terminal of the component to be welded and then welding it, but it can not accumulate with too much solder, which makes it easy to cause the solder joint and the solder joint Between the short circuit.

4. Welding must be reliable, to ensure the conductivity. In order to make the solder joint has good electrical conductivity, it is necessary to prevent Weld. Weld is the solder and the surface of the solder did not form an alloy structure, but simply attached to the surface of the metal being welded. In the welding, if only part of the formation of alloy, and the rest did not form the alloy, then the solder joints in the short term can also pass the current, with the instrument measurement is also difficult to find the problem. But with the passage of time, there is no alloy surface will be oxidized, then there will be when the phenomenon of broken off, which is bound to cause the quality of the product title.

In short, the quality of the solder joints should be: solder bright, smooth; solder layer evenly thin, and the size of the pad with the appropriate size, the combination of the visible vaguely visible; solder sufficient, into a skirt spread; Hole, no flux residue.Pcb design in china

2. When welding temperature, time should be appropriate, heating evenly. When welding, the solder and the welding metal are heated to the welding temperature so that the molten solder is wetted and diffused on the surface of the metal to be welded and forms a metal compound. Therefore, to ensure that the solder joints are firm, be sure to have the appropriate welding temperature. At a sufficiently high temperature, the solder can be sufficiently wetted and sufficiently diffused to form an alloy layer. Excessive temperature is not conducive to welding. The welding time has a great influence on the solderability of the solder, the welding element, and the formation of the bonding layer. Correctly grasping the welding time is the key to high quality welding.

3. The solder joints should have sufficient mechanical strength. In order to ensure that the weldment is subject to vibration or shock will not fall off, loose, therefore, require the solder joints to have sufficient mechanical strength. In order to have sufficient mechanical strength of the solder joint, it is generally possible to use the method of bending the lead terminal of the component to be welded and then welding it, but it can not accumulate with too much solder, which makes it easy to cause the solder joint and the solder joint Between the short circuit.

4. Welding must be reliable, to ensure the conductivity. In order to make the solder joint has good electrical conductivity, it is necessary to prevent Weld. Weld is the solder and the surface of the solder did not form an alloy structure, but simply attached to the surface of the metal being welded. In the welding, if only part of the formation of alloy, and the rest did not form the alloy, then the solder joints in the short term can also pass the current, with the instrument measurement is also difficult to find the problem. But with the passage of time, there is no alloy surface will be oxidized, then there will be when the phenomenon of broken off, which is bound to cause the quality of the product title.

In short, the quality of the solder joints should be: solder bright, smooth; solder layer evenly thin, and the size of the pad with the appropriate size, the combination of the visible vaguely visible; solder sufficient, into a skirt spread; Hole, no flux residue.Pcb design in china